Produk busa urethane telah menjadi popular dalam beberapa industri kerana kelabitannya dan keupayaan tahanannya. Pelanggan mempunyai keyakinan dalam produk busa urethane mereka untuk kedua-dua pemanisan dan pengeleman serta pembungkusan, sama ada dalam arena pembinaan atau automotif. Produk busa urethane boleh digunakan dalam pelbagai aplikasi dan menawarkan pelbagai faedah, termasuk simpanan tenaga yang penting, keupayaan tahanan luar biasa & kualiti.

Insulasi busa urethane dipertimbangkan secara prospektif sebagai salah satu pilihan terbaik semasa pembinaan anda. Penggunaan produk insulasi busa urethane boleh memberi faedah kepada bangunan dengan meningkatkan kecekapan tenaga, mengurangkan tahap bunyi dan membuatkan persekitaran menjadi selesa. Selain itu, insulasi busa urethane berfungsi sebagai penghalang air dan kelembapan, melindungi struktur terhadap kuman & lumut yang boleh menyebabkan kerosakan yang serius.

Kelebihan lain bagi item busa urethane dalam pembinaan dan konstrksi adalah kepelbagaian yang luar biasa. Busa urethane boleh digunakan untuk memisahkan seluruh bangunan, termasuk dinding, attap dan atap. Untuk memastikan penyekatan yang berkesan tanpa merosakkan arsitektur bangunan anda, maka aplikasi penyemprotan penyekatan busa urethane dalam ruang sempit atau sukar dicapai.

Produk pemalar busa urethane tersedia di pasaran dan membuat keputusan anda bermaksud bahawa anda perlu mengambil kira faktor-faktor yang berbeza. Kecekapan tenaga, nilai R dan ciri-ciri lain pemalar menentukan produk mana yang paling sesuai untuk tugasan ini.

Contoh sempurna jenis ini adalah pemalar busa semburan sel tertutup, yang cemerlang dalam nilai R apabila dibandingkan dengan sel terbuka. Oleh itu, penyelesaian ini menawarkan pengurangan cekap kehilangan dan penambahan haba serta keupayaan penyegelan udara yang kuat. Pemalar busa sel tertutup sangat sesuai untuk kawasan yang rentan kepada kemasukan kelembapan dan air.

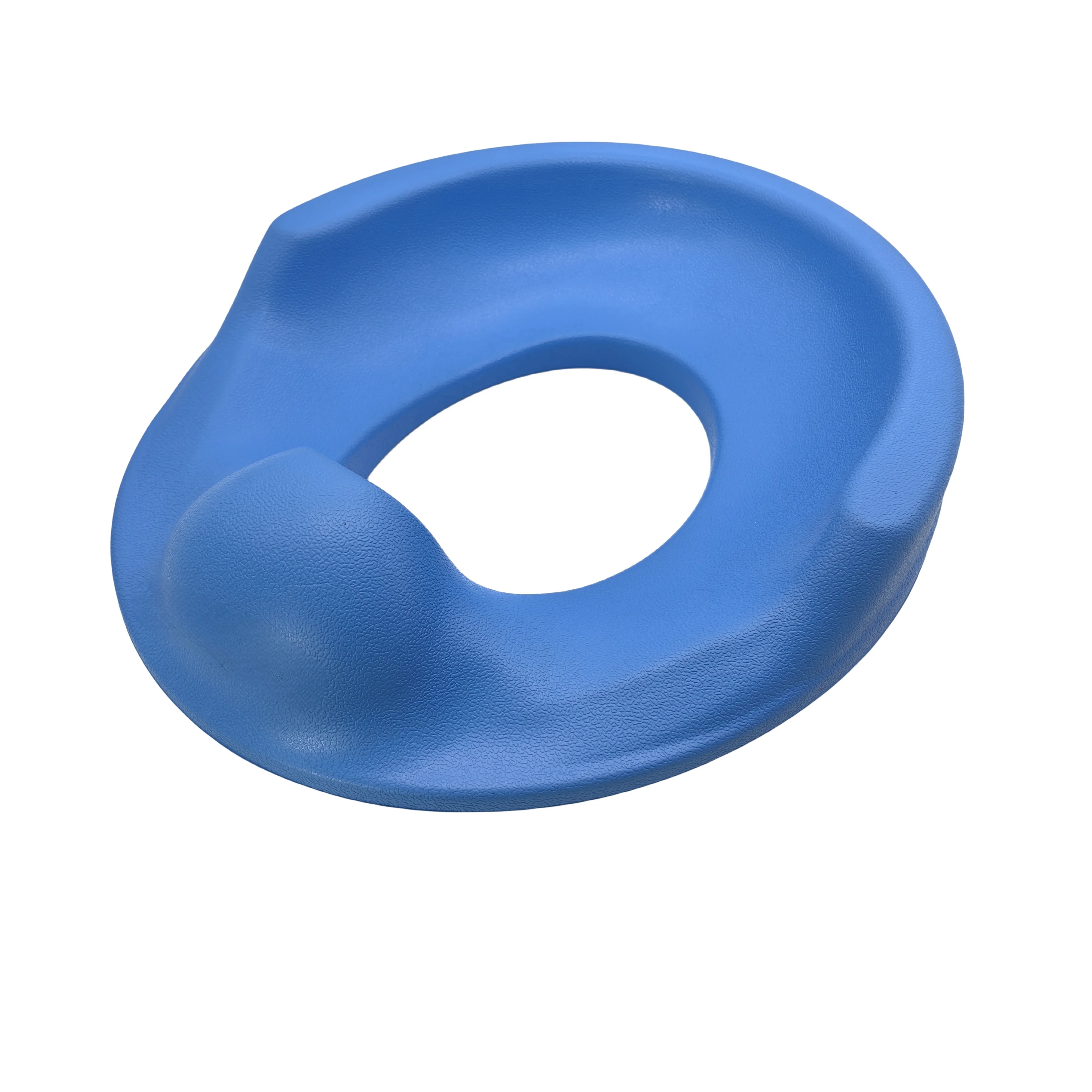

Akhirnya, insulasi bus semprot sel terbuka adalah pilihan kelas atas lain yang menawarkan pemadam bunyi dan pengurangan bunyi yang efektif di antara ruang. Selain itu, insulasi seperti ini menyediakan beberapa insulasi dan membolehkan sirkulasi udara. Insulasi bus semprot sel terbuka adalah pilihan yang betul untuk pemasangan di loteng dan ruang lain yang memerlukan ventilasi. Orang-orang di seluruh Amerika Syarikat memilih pengepunan bus urethane untuk perabot kerana keselesaan dan ketahanannya. Walau bagaimanapun, tidak semua pengepunan bus urethane dicipta sama, yang membuatkan pemilihan jenis yang optimal menjadi tugas yang mencabar. Ia adalah perlu untuk mempertimbangkan faktor-faktor yang berbeza, seperti kekerasan, ketumpatan, ketebalan, dan penyusutan untuk memilih jenis pengepunan yang betul. Bus pengepunan dengan ketumpatan tinggi sesuai untuk kerusi dan sofa yang banyak digunakan. Pengepunan bus yang keras adalah tegar dan dianggap paling tahan lama dan paling selesa untuk tempoh duduk yang panjang. Pengepunan bus dengan ketumpatan rendah kurang tahan lama tetapi berfungsi sebagai pengepunan, yang merupakan pilihan yang baik untuk penggunaan sementara atau estetik. Ketebalan juga perlu dipertimbangkan kerana pengepunan yang lebih tebal lebih selesa tetapi boleh mahal untuk dihasilkan. Akhirnya, faktor penyusutan adalah penting kerana semakin tinggi penyusutan, semakin mudah bus untuk didepresurkan dan pulih kepada bentuk asalnya, yang penting untuk kawasan dengan trafik ramai. Penyekatan bus urethane juga digunakan dalam pelbagai industri di seluruh Amerika Syarikat di mana barang rapuh dihantar. Penyekatan ini sangat melindungi dan memastikan barang-barang tersebut dikirimkan dalam bentuk asalnya. Ia boleh digunakan semula dan ramah lingkungan kerana tahan terhadap kapak dan penguraian bakteria.

Tarikan utama kaedah pembungkusan busa urethane adalah sejauh mana ia melindungi. Dibentuk mengikut bentuk objek yang dibawa, bungkusan yang tersusun ini membantu memastikan barang tidak bergerak terlalu banyak semasa penghantaran (yang boleh menyebabkan kembalian yang memalukan dan pelanggan yang tidak puas hati).

Kerana ciri-ciri bahan seperti sifat bahan mereka, produk PU atau getah adalah tahan lama dan ringan sementara tahan panas dan sejuk. Mereka juga boleh bertahan lama. Produk busa urethane Ronghe akan memuaskan semua keperluan anda sama ada jenis komponen PU, bahagian getah atau komponen plastik yang diperlukan dan syarat-syarat keras yang digunakan.

Sekiranya sukar untuk mengeluar sebuah item, Ronghe akan menggunakan produk busa urethane berkualiti tinggi untuk menyesuaikan dengan tepat dimensi dan bentuk produk kepada spesifikasi khas anda. Kami mempunyai banyak tahun pengalaman dalam pelbagai pasaran termasuk penyesuaian produk busa PU, tali penyegelan, penyesuaian produk plastik, penyesuaian bahagian terbentuk getah, dll. dan kami ingin bekerjasama dengan anda.

Kami mengawasi setiap proses pembuatan produk busa urethane kami supaya dapat memenuhi keperluan pelanggan kami pada masa yang ditetapkan serta dalam kuantiti berkualiti tinggi. Kami membina penyelesaian tersuai pakar yang dibuat daripada busa PU, getah, dan bahan lain yang memenuhi keperluan individu mereka. Anda boleh yakin mendapat perkhidmatan cemerlang kerana kami menawarkan program purnajual yang memberikan bantuan satu lawan satu.

Qinghe Ronghe urethane foam products Products Co. Ltd. ditubuhkan pada tahun 2015 adalah sebuah enterprise yang khusus dalam pembuatan produk keluli serta komponen plastik.Produk utama PU Foam Produk Plastik Produk Keluli Dibentuk dan Segel. Produk dihantar ke Eropah Amerika Afrika Asia Tenggara dan negara-negara lain.