Jednym z najtrwalszych i powszechnie stosowanych obecnie materiałów jest pianka uretanowa o dużej gęstości. Ze względu na swoje wyjątkowe właściwości i wszechstronność, ten przełomowy materiał znajduje liczne zastosowania w różnych gałęziach przemysłu, od budownictwa po sztukę piękną. Dlatego dzisiaj przyjrzymy się bliżej światu HDU i temu, dlaczego zmienia on sposób produkcji, projektowania i innych sektorów.

Wdrożenie HDU nie ogranicza się tylko do codziennych zastosowań, ponieważ przełomowe postępy poczyniono w sektorach budownictwa, motoryzacji i inżynierii lotniczej. Dzięki swojej lekkości, a jednocześnie niewiarygodnie mocnej konstrukcji, niski poziom energii wymagany w transporcie i zużycie paliwa w samochodach przyniosły ogromne korzyści. W świecie architektury panele HDU zyskały pewną popularność ze względu na ich zdolność do naśladowania kamienia lub drewna, przy jednoczesnym zmniejszeniu ciężaru i niezbędnym projekcie konstrukcyjnym budynków, zmniejszającym obciążenie budynku na aktywność sejsmiczną. Co więcej, obrabialność HDU ustępuje złożonym ozdobnikom architektonicznym i oznakowaniu, umożliwiając nieograniczoną kreatywność stylu. Kiedy myślimy o przyszłości, HDU ma ogromne możliwości dostosowywania i integracji z inteligentnymi technologiami, co czyni go jednym z kluczowych produktów w zakresie zrównoważonego życia i rozwoju obszarów miejskich.

Produkty HDU charakteryzują się długą żywotnością i są niezwykle trwałe w porównaniu do wielu innych materiałów. Ponieważ są odporne na wilgoć i szkodniki, produkty na bazie HDU mają dłuższą żywotność niż inne, z wyjątkiem tego, że nic nie może ich uszkodzić w najtrudniejszych warunkach. Z tego powodu HDU pozostaje stabilny wymiarowo nawet w najsurowszych klimatach i nie ulega rozszerzaniu ani kurczeniu termicznemu w niewielkim stopniu lub wcale, gdy jest używany do bardzo precyzyjnych zastosowań, takich jak wytwarzanie form lub rzeźbienie. Materiał HDU jest również bardzo lekki i łatwy w obróbce, co prowadzi do szybszej realizacji projektów bez kompromisów w zakresie zestawu konstrukcyjnego. Jest materiałem angielskim. Ponadto AJW Broadway zapewnia projektantom i architektom elastyczność w osiąganiu ich estetycznej wizji poprzez malowanie, bejcowanie lub metalizację na podłożu. niezliczone możliwości wykończenia.

Wykorzystanie zrównoważonego rozwoju jako podstawy HDU sprawia, że ta pianka cementowa jest towarem, którego nie można znaleźć w tradycyjnych zastosowaniach pianek. Ponieważ HDU nadający się do recyklingu jest produkowany z mniej toksycznych związków, stanowi obietnicę procesu o bardziej zamkniętym obiegu, w którym stare przedmioty są ponownie wykorzystywane, a nie wyrzucane. Z biegiem lat HDU stosowane w budownictwie przyczyniły się do zmniejszenia śladu węglowego dzięki ulepszonej izolacji, która zmniejsza zapotrzebowanie na ogrzewanie i chłodzenie dzięki swoim energooszczędnym właściwościom. Jedną z korzyści dla środowiska wynikających z warstwowego HDU jest uniknięcie tworzenia odpadów w zasobach i składowiskach poprzez wydłużenie żywotności. Budynki nie muszą być wymieniane tak często. Wybierając HDU, robisz świadomy krok w kierunku czystszej przyszłości.

Aby zagwarantować pomyślny projekt, należy wziąć pod uwagę wiele zmiennych przy podejmowaniu decyzji o wyborze odpowiedniej HDU. Gęstość – mierzona w funtach na stopę sześcienną (PCF), jest ważna dla określenia wytrzymałości i zastosowania materiałów. Większą gęstość należy stosować w przypadku części konstrukcyjnych wymagających większej wytrzymałości i minimalnej wartości wymaganych właściwości w FE Simulations, co oznacza, że unikamy niższych gęstości, bardziej przypominających pomoce w modelowaniu. Ważne jest, aby znać środowisko, w którym pianka będzie stosowana; W przypadku instalacji na zewnątrz wymagane są preparaty odporne na wilgoć. Ponadto, gotowy element produkcji (jeśli jest to na przykład delikatna rzeźba) lub wymaga gładkiego pomalowania, pokrycia metalem itp., określi, jakiej tekstury i twardości pianki potrzebujesz. Współpraca z doświadczonymi dostawcami i producentami może uprościć proces wyboru HDU, zapewniając, że wybrany materiał spełnia wszystkie kryteria wydajności, a jednocześnie mieści się w wizji projektu.

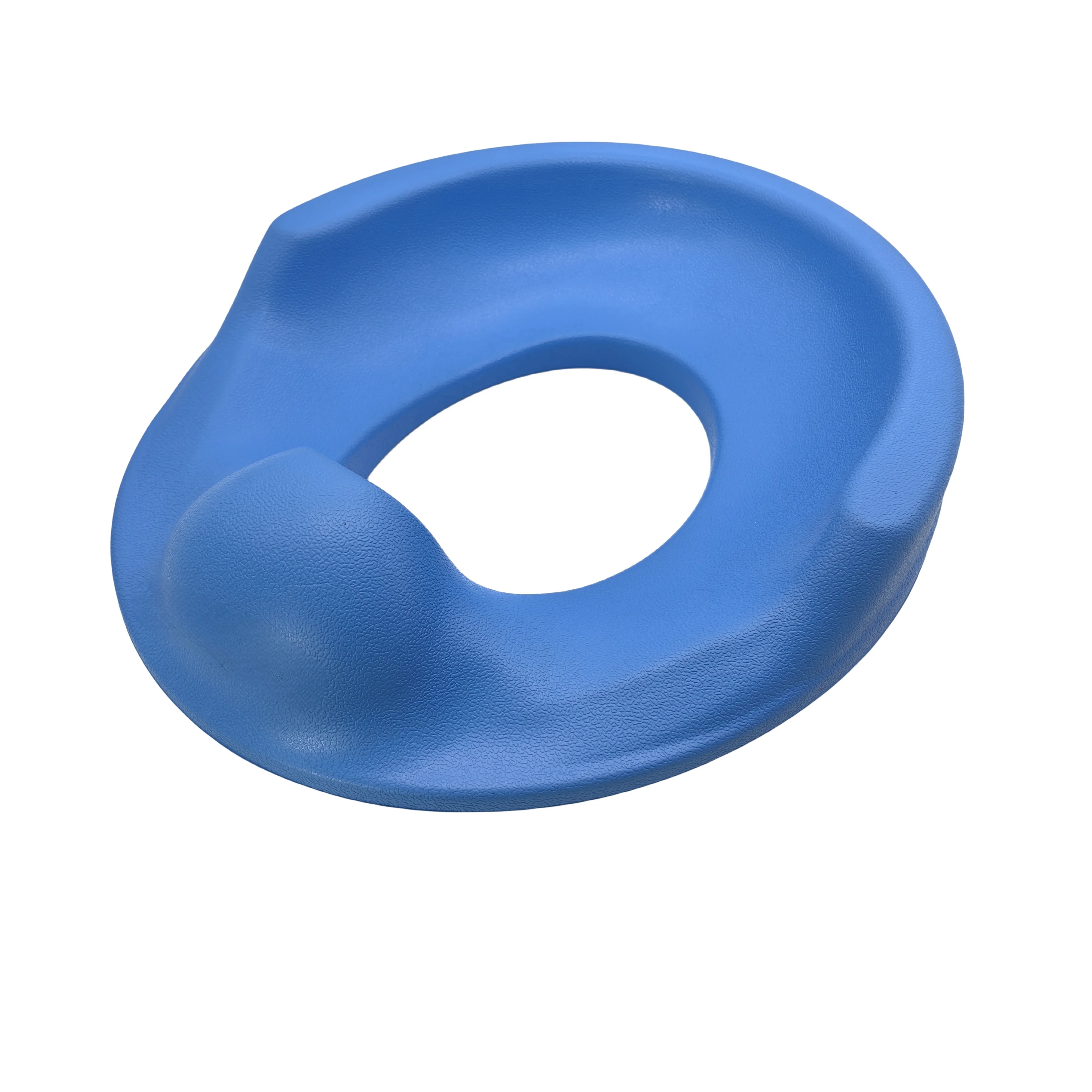

Qinghe Ronghe Rubber Products Co. Ltd. utworzona w 2015 roku jest przedsiębiorstwem specjalizującym się w produkcji wyrobów gumowych, a także komponentów z tworzyw sztucznych. Główne produkty: pianka uretanowa o dużej gęstości Wyroby z tworzyw sztucznych Części i uszczelki gumowe. Produkty są wysyłane do Europy, Ameryki, Afryki, Azji Południowo-Wschodniej i innych krajów.

Ze względu na swoje właściwości fizyczne, takie jak właściwości materiału, produkty z PU lub gumy są trwałe i lekkie, a jednocześnie odporne na zimno i ciepło. Mogą również służyć przez długi czas. Produkty Ronghe spełniają Twoje potrzeby niezależnie od rodzaju pianki uretanowej o dużej gęstości, np. jakich części gumowych lub plastikowych potrzebujesz i w jakim trudnym środowisku są stosowane

Niezależnie od trudności wytworzenia przedmiotu, Ronghe użyje wysokiej jakości surowców, aby precyzyjnie dopasować piankę uretanową o dużej gęstości i kształt produktu, aby spełnić Twoje specyficzne potrzeby. Mamy bogate doświadczenie na wielu rynkach, takich jak dostosowywanie produktów z pianki PU, w tym pasków uszczelniających, niestandardowych produktów z tworzyw sztucznych, części wykonanych z gumy itp. Rozważamy współpracę z Tobą.

Zapewniamy, że kontrolujemy każdą procedurę dotyczącą pianki uretanowej o dużej gęstości, aby zapewnić terminowość, jakość i ilość dostaw, koncentrując się na dostarczaniu profesjonalnych i odpowiednio dostosowanych rozwiązań dla produktów PU, w tym produktów gumowych i plastikowych, aby spełnić Twoje specyficzne wymagania. We oferujemy pełny system wsparcia posprzedażowego, który obejmuje wsparcie indywidualne, które może szybko rozwiązać wszelkie mogące się pojawić problemy, dzięki czemu możesz mieć pewność, że zaoferujemy Ci świetną obsługę.