Polyuretanskum (PU) - ett mångsidigt och lätt under-material Det används flitigt i praktiskt taget alla branscher för sina unika isoleringsegenskaper. Ett slags PU-skum, dvs OEM polyuretan-tejp, skapas för de speciella funktionerna av tillverkarna. Följande artikel tar dig in i OEM-polyuretanskumvärlden: från de olika typerna som används i olika projekt till dess revolutionerande tillämpningar inom industrier som fordon och konstruktion, eller hur det kan jämföras med andra isoleringsprodukter.

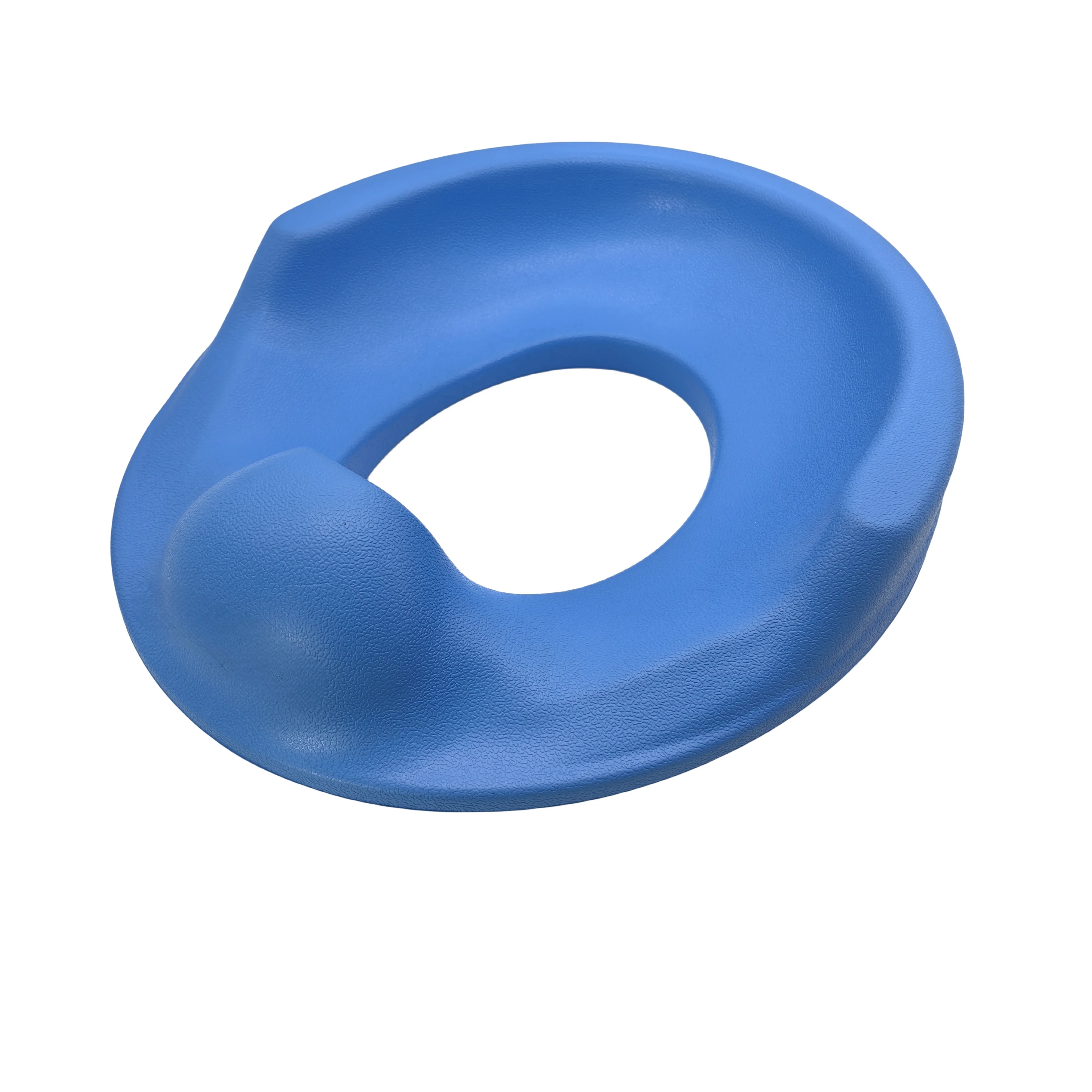

Det här är mer som när Original Equipment Manufacturers (OEM) tar in polyuretanskum för att spela, vilket blir en sprudlande form av intressant kreativt böjd utrustning och funktioner som du behöver göra för hand. Det är ett av få skum med slutna celler med hög tryckhållfasthet, låg vattenabsorption och goda isoleringsegenskaper. Sådant skum kan anpassas för att uppfylla individuella beställningar, såsom i färgförändringar, skillnader i densitet eller hårdhet och konduktivitet.

Hur man väljer det bästa OEM polyuretanskum för ditt projekt

Det finns många viktiga saker att tänka på när du ger dig ut i urvalsprocessen för att välja perfekt OEM polyuretanskum. Det första, och utan tvekan viktigaste steget, är att identifiera exakt vad ditt projekt kräver av skummet – oavsett om det är en viss nivå av isolering eller till och med bara hur de reagerar på miljöfaktorer. Några faktorer du måste tänka på är: skummets densitet och hårdhet. Större densitet och hårdhet förbättrar inte bara isolering, dämpning utan kräver också att man betalar ett högre pris med ökad vikt.

Man bör heller inte glömma att skummets värmeledningsförmåga Ju lägre värmeledningsförmåga, desto bättre isolerar det. Välja topp-oem-polyeutan-skum-för-ditt-projekt Genom att ta hänsyn till dessa ovannämnda faktorer kan du fatta det mest välgrundade beslutet som passar ditt projekt.

Detta är något som vi har sett utnyttjat på en mängd olika sätt inom fordonsindustrin. Det används ofta i sätes- och interiörisoleringsmaterial för instrumentbrädor samt torrpaneler på dörrlister, golvljuddämpare, sätessvetsflänsar eller andra fordonstillämpningar för att minska väginducerat buller. Det som gör OEM polyuretanskum speciellt är dess flexibilitet och justerbarhet på grund av vilken det effektivt kan konturera till vilken form som helst, vilket resulterar i perfekt passform med bästa isolering.

I biltillämpningar tillverkades bränsletankar med OEM polyuretanskum för första gången. Användningen av de skumfyllda varianterna minskar risken för explosion och skador om det någonsin skulle inträffa en olycka, vilket visar hur denna typ av skum spelar en avgörande roll för att säkerställa att driftsstandarder följs strikt inom den typen av industri.

OEM polyuretanskum lånas ut till ett antal applikationer inom byggsektorn och har uppnått betydande lönsamhet från det. Denna typ av skum används ofta för isolering, tätning och dämpning samt ljudisolering. En av de mest grundläggande anledningarna till att OEM polyuretanskum rekommenderas för användning i byggapplikationer beror på dess förmåga att täta praktiskt taget alla luckor eller sprickor - oavsett hur små nämnda öppningar kan vara.

Dessutom erbjuder OEM polyuretanskum en nivå av motståndskraft mot fukt/mögel och mögel.getProperty(;; vilket gör det till ett utmärkt alternativ för användning i fuktiga miljöer. Tillverkad av lätt men extremt hållbart aluminium, belysningen levereras och installeras lätt för att förstärka dess plats som ett av konstruktionens favoritmaterial.

Det finns två huvudtyper av polyuretanskum: öppna celler och slutna celler. Låg densitet och låg tryckhållfasthet betyder att det är ett skum med öppna celler, medan det har en hög kompressionsmotstånd mot vikt på mer än 2lb/ft3 (~32kg/m^) i fallet med skum med slutna celler. När det gäller isolering framstår skum med slutna celler som den självklara lösningen för att uppnå lägre värmeledningsförmåga och minskat vatteninnehåll.

Skum med slutna celler är en utmärkt ångspärr och kommer dramatiskt att minska isoleringsföroreningar från inrusande fukt. Detta är särskilt viktigt i områden med höga luftfuktighetsnivåer, eftersom fuktinträngning kan minska isoleringsförmågan och främja mögel- eller mögelutveckling.

Faktum är att OEM polyuretanskum har visat sig gång på gång som ett lättviktsmaterial som lätt massproduceras i nästan vilken form som helst som gör att det kan användas inom bilbyggnadsindustrin. Därför är det avgörande att specificera rätt OEM polyuretanskum för ditt projekt för att uppfylla kraven med fokus på tre nyckelområden: Skumdensitet och hårdhet, Värmeledningsförmåga och driftsmiljö. Det blir snabbt den valda isoleringen, med skum med slutna celler som har hög värmeledningsförmåga och fuktbeständighet.

Vi säkerställer att vi kontrollerar varje tillverkningsprocess för att säkerställa att vi uppfyller dina behov av förnödenheter när det gäller kvalitet, tid och kvantitet. Vi fokuserar på att skapa professionella och lämpliga skräddarsydda lösningar för oem polyuretanskum samt gummi- och plastprodukter som kommer att tillfredsställa dina specifika krav. Vi garanterar den bästa servicen då vi har ett eftermarknadssystem som ger en-till-en-hjälp.

På grund av sina egenskaper kan PU-skum och gummiprodukter vara både oem polyuretanskum och lätta samtidigt som de är resistenta mot kyla och värme. De är också långvariga i sin tid Ronghes produkter uppfyller dina krav oavsett typ av PU-produkt inklusive gummidelar plastdelar du behöver och vilken tuff miljö de används i

Oavsett svårigheten att producera produkter, kan Ronghe använda högkvalitativa råmaterial för att exakt justera föremålens speciella dimensioner och form för att möta dina exakta behov. Vi har många års erfarenhet av att betjäna flera marknader, inklusive anpassning av oem polyuretanskum, tätningsremsor anpassade plastprodukter, formar gjorda av gummi till exempel. Vi ser fram emot att arbeta med dig.

Qinghe Ronghe Rubber Products Co. Ltd. grundades 2015. Det är ett företag som är specialiserat på tillverkning av plastprodukter och gummikomponenter. Huvudprodukter PU-skumprodukter Plastprodukter Gummiformade delar och oem polyuretanskum. Export till Europa Amerika och Afrika samt Sydostasien.