İnşaattan mobilya imalatına kadar pek çok sektörde poliüretan köpük, modern kimyanın çığır açan bir mucizesini temsil ediyor. Bu muhteşem madde inanılmaz derecede çok yönlü ve yüksek performanslıdır; dünyamızın dönmesini sağlar. Üretim süreci için poliüretan köpüğün nüanslarına daha derin bir bakış, sürdürülebilirlik, yalıtım özellikleri ve geniş yelpazedeki endüstriyel kullanımlar ve titizlikle hazırlanmış lüks konfor ürünleri için çaba göstermektedir. Derinlere indikçe poliüretan köpüğün aslında ne kadar derin bir yere sahip olduğu daha da netleşiyor.

Her sert poliüretan köpük ürününün kalbinde, polimerizasyon adı verilen, dikkatle hazırlanmış bir kimyasal reaksiyon bulunur. İki ana bileşenin karışımıdır: diizosiyanatlar ve polioller. Bunlar, izosiyanatlara kimyasal olarak bağlanan, ısıyla sertleşen polimerlerdir ve hidroksil grupları tarafından sonlandırılan tekrarlanan birimlerden oluşan moleküller içerirler. Bu maddeler gerekli sıcaklık ve basınçta birleşerek çeşitli yoğunluk, dayanıklılık ve esneklikte kalıplanabilen köpük oluşturur. Ayrıca katalizörler, şişirici maddeler ve katkı maddeleri bu özelliklerin daha da ayarlanmasından sorumludur; bu özellikler olmadan açık hücreli köpüklerin (ses emici olarak en iyi şekilde kullanılır) veya mükemmel yalıtım değerine sahip kapalı hücreli köpüğün mümkün olmayacağı anlamına gelir.

Klasik köpük ürün işlemeyle ilgili çevresel etkilerin ışığında araştırmacılar ve üreticiler, daha yeşil poliüretan ürünler geliştirme misyonundalar. Soya fasulyesi, hint yağı ve hatta geri dönüştürülmüş PET şişeler gibi yenilenebilir kaynaklardan gelebilecek biyo bazlı poliolleri kullanıyor. Bu sürdürülebilir değişimler, fosil yakıt bağımlılığını da önemli ölçüde azaltacak ve aynı zamanda yüksek performansa ulaşacak. Ek olarak, şişirici madde teknolojisindeki son gelişmeler, HCFC-141b ve HFC'ler 245fa ve123 için düşük küresel ısınma potansiyeline sahip (GWP) ikamelerin kullanımına olanak sağlamıştır. Ve bu bile sizin için yeterince çevreci değilse bile biyolojik olarak parçalanabilen poliüretanların geri dönüşümü ve geliştirilmesi de her zaman söz konusudur.

Isı yalıtım yeteneği, poliüretan köpüğün benzersiz özelliğidir ve bu da onu olağanüstü kılar. Bunun nedeni büyük ölçüde kapalı hücreli türlerin sıkı, birbirine kenetlenen yapısından kaynaklanmaktadır; bu yapı, esasen hava ve nem geçirmez bir bariyer oluşturur ve bu da gereksiz ısı nedeniyle hareketi büyük ölçüde azaltır. Sonuç olarak bu, ısıtma ve soğutmadan kaynaklanan emisyon miktarını azaltarak çok az maliyetle enerji açısından son derece verimli binalar yaratır. Ayrıca köpük, en ince boşlukları bile tamamen doldurabilir, böylece hava sızmasını azaltmaya yardımcı olarak genel enerji verimliliğinizi artırır. Poliüretan köpük yalıtımı, gıda güvenliğini artırmak ve atıkların azaltılmasını sağlamak amacıyla soğuk zincir lojistiğinde nakliye sırasında bozulabilen ürünlerin korunmasında önemli bir bileşendir.

Poliüretan köpük, mobilyalarda konfor sağlamaktan soğutma ünitelerindeki yalıtımı yönetmeye kadar çok yönlülüğüyle bilinir. Benimsenmesi otomotiv endüstrisinde hafiflik açısından iyidir; burada ağırlığa katkıda bulunmadan hem yapısal hem de gürültü azaltıcı faydalar sunar; hafif ağırlıkların daha fazlasına ihtiyaç duymadığı bir şeydir. Sağlık sektöründe poliüretan köpük, hipoalerjenik ve antibakteriyel özellikleri sayesinde doğal doku benzeri kıvamı nedeniyle protezlerde ve hastane yataklarında kullanılmaktadır. Spor ekipmanlarında şok emici özelliği ile sporcuların fiziksel aktivite yaparken güvenliğini arttırır. Moda endüstrisinde de poliüretan köpük, yenilik uğruna dayanıklılıktan ödün vermeden üzerinde durmaksızın hareket ettiğiniz giysilerde büyük miktarda yastıklama ve konfor sağlar.

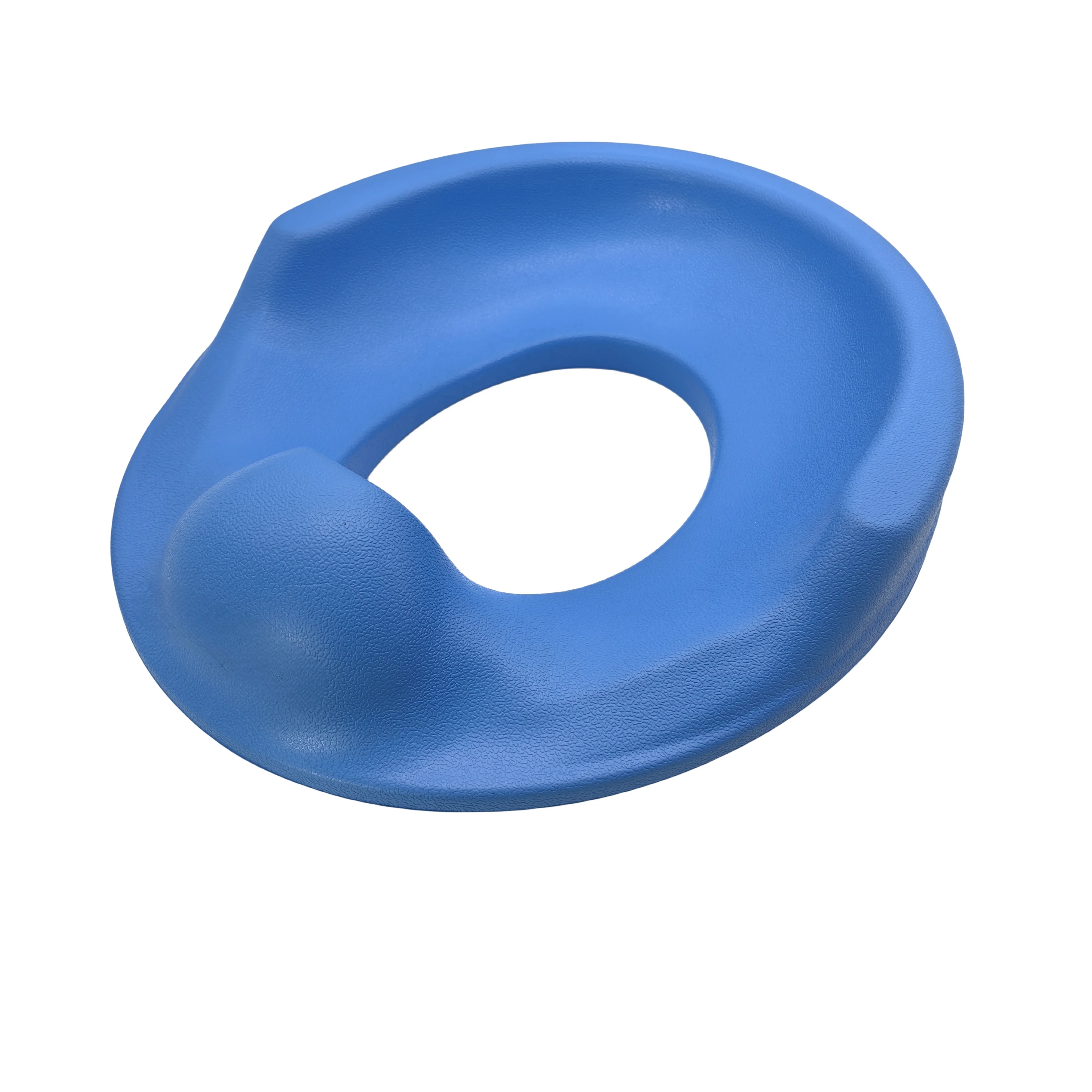

Ürün üretmenin zorluğu ne olursa olsun, Ronghe, ihtiyaçlarınızı tam olarak karşılayacak şekilde ürünün özel boyutlarını ve şeklini hassas bir şekilde ayarlamak için yüksek kaliteli hammadde kullanabilir. Poliüretan köpük ürününün özelleştirilmesi, plastik ürünlerin özelleştirilmesi için sızdırmazlık şeridi, örneğin kauçuktan yapılmış kalıplar da dahil olmak üzere birçok pazara hizmet verme konusunda uzun yıllara dayanan deneyime sahibiz. Sizinle çalışmak için sabırsızlanıyoruz.

Qinghe Ronghe Kauçuk Ürünleri Co. Ltd. 2015 yılında kurulmuştur. Plastik ürünler ve kauçuk bileşenler üretiminde uzmanlaşmış bir firmadır. Ana Ürünler PU Köpük Ürünleri Plastik Ürünler Kauçuk Kalıp Parçaları ve poliüretan köpük ürünü. Avrupa Amerika ve Afrika'nın yanı sıra Güneydoğu Asya'ya da ihracat yapılmaktadır.

İster PU köpük ürünler olsun, ister diğer kauçuk ürünler olsun, malzemelerinin poliüretan köpük ürünü olması sayesinde sağlam ve dayanıklıdırlar Hafiftirler Ayrıca ısıya dayanıklı soğuğa dayanıklı olup uzun ömürlü olabilirler Hangi tür PU köpük ürünleri kauçuk ürünlerdir veya plastik bileşenlere ihtiyacınız var veya nasıl bir ortamda bulunuyorsunuz, Ronghe ürünlerinin ihtiyaçlarınızı karşılayabileceğinden ve en güvenilir ortağınıza dönüşebileceğinden eminim.

Zaman, kalite ve miktar açısından doğru tedarik gereksinimlerine sahip olduğunuzdan emin olmak için poliüretan köpük ürünleri her üretim sürecini kontrol ediyoruz. Odak noktamız, kauçuk ürünler, plastik ürünler de dahil olmak üzere, bireysel gereksinimlerinizi karşılayan PU köpük ürünleri için verimli ve özelleştirilmiş çözümler sunmaktır. Bire bir desteği içeren bir satış sonrası destek sistemimiz olduğundan, yüksek kaliteli hizmet garanti edilir.